Production Up & Costs Down with Precision Lamination Stacking Solution

THE CUSTOMER CHALLENGE

ABB, a manufacturer of motor laminations for the electric motors industry, needed a new process for its lamination production line that eliminated inefficiencies caused by the lamination chutes.

Hundreds of inches of motor lamination would go through the chutes before an inspection by an operator. If there was a quality issue, it could be 30-45 minutes before an operator could see it and stop the process.

With 60 tons of material moving through the line each day, ABB was looking for a solution to reduce the loss of scrap material and production time caused by the current setup of the lamination chutes. The company also was looking to improve the line’s safety by reducing the overall physical labor, specifically, time spent lifting heavy bundles.

The company turned to Machine Concepts to design, engineer and build an innovative concept to remove the lamination chutes, yet ensure the laminations were precisely aligned in order to improve overall productivity.

THE SOLUTION

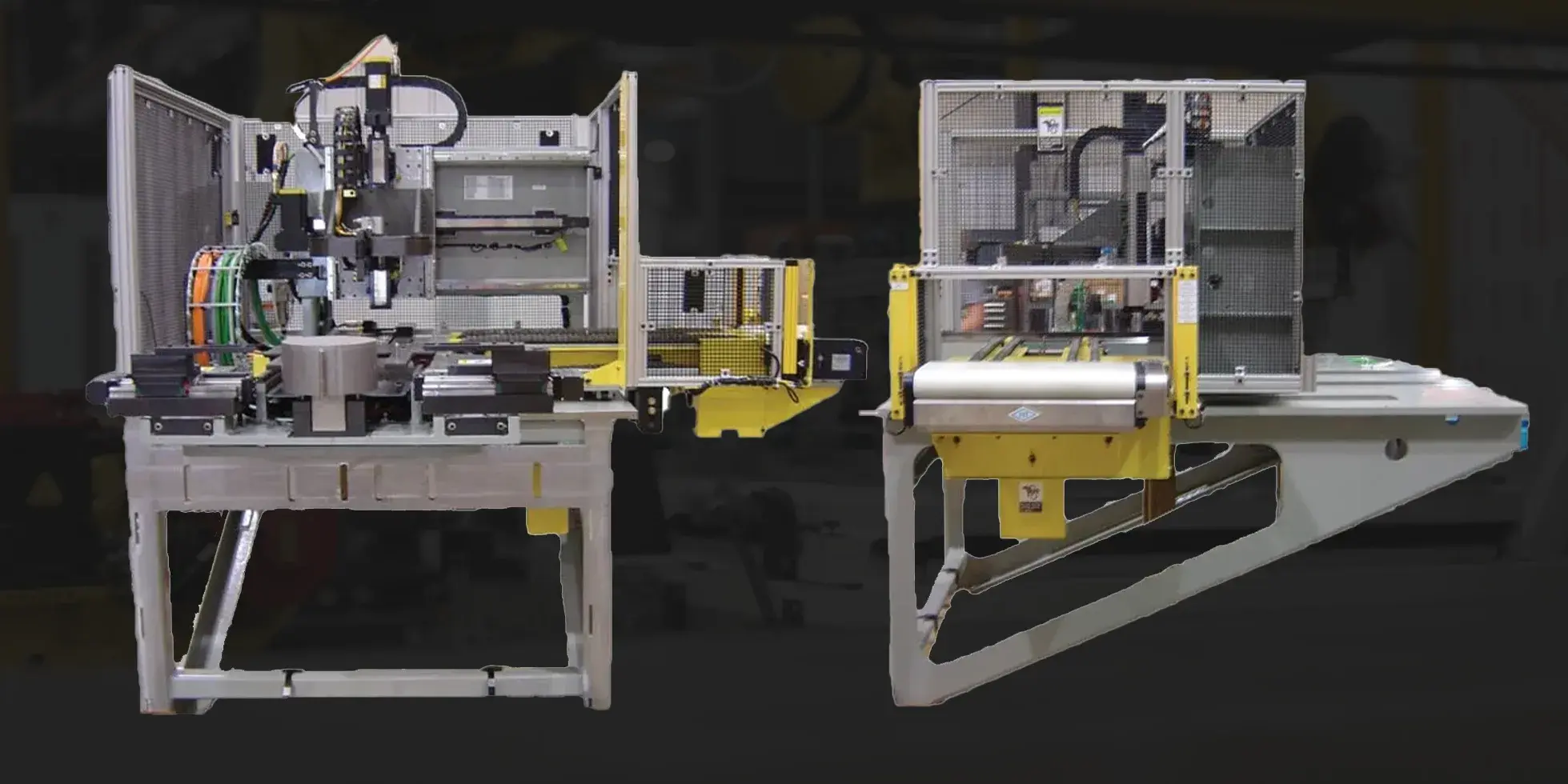

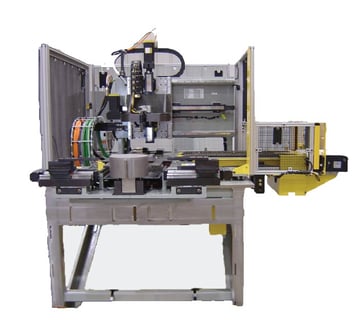

Machine Concepts pioneered an all-new stacking system that eliminated the chutes and uses lightweight, easy-to-operate tools. Engineered for extreme precision, the stacking system perfectly aligns each lamination slot so the stack can go straight to the welding process with no need for lamination chutes for alignment.

As the parts are cut off the end of the die, they slide over a mandrel assembly with locating pins down to a shuttle plate with another set of locating pins to maintain alignment. When the shuttle plate reaches its target stack height, a finger escapement engages the top mandrel and catches the parts allowing the system to keep running while the lower mandrel is retracted.

Once the lower mandrel is retracted the shuttle plate can move to a pickup point that will allow a transfer system to pick up the parts, raise and transfer it to the unload area. While the parts are being transferred to the unload station the shuttle plate returns to the home position underneath the mandrel assembly.

Once the shuttle plate is at the home position, the lower mandrel raises to engage the upper mandrel and the finger escapement retracts allowing the parts to stack on the shuttle plate. When the transfer system reaches the unload station, it will place the parts on a conveyor with location pins to keep alignment.

The transfer system will keep stacking bundles of parts until the desired stack height is achieved. Once achieved, the locating pins will lower and the conveyor will present the stack of parts to the operator to wire and prepare for the annealing process.

THE STACKING SYSTEM’S KEY TECHNOLOGIES

- Servo driven finger escapement

- Mandrel assembly with rocket style locating pins

- Servo driven shuttle plate with locating pins

- Servo driven transfer system with gripper and movable locating pins for different parts

- Conveyor system with locating pins

THE RESULTS

ABB achieved ROI on the solution in only nine months -- and that was only based on looking at the costs saved in reducing scrap material. In reality, payback was achieved even sooner when taking into account improved operator safety and overall increased productivity.

ABB achieved ROI on the solution in only nine months -- and that was only based on looking at the costs saved in reducing scrap material. In reality, payback was achieved even sooner when taking into account improved operator safety and overall increased productivity.

Due to the proven success, ABB has since invested in two more lamination stacking systems for its production facility.

At Machine Concepts, we design and build a wide range of motor lamination stacking systems and other press room equipment. With extensive experience in below bed stacking, above bed stacking and end of crop stackings, we can engineer innovative solutions for the most demanding requirements.

For more information, contact Machine Concepts: 419-628-3498 / machineconcepts.com/contact.