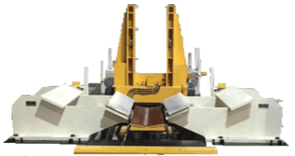

New Design of Coil Upender Increases Productivity and Safety

THE CUSTOMER CHALLENGE

Constellium, a global aluminum mill company, was looking for a machinery builder who could completely redesign its coil upender process to improve operator efficiency and safety while decreasing costs. The existing line’s constant maintenance issues were costing time and money. The company selected Machine Concepts to engineer and build an innovative, high-quality solution with a long-term life expectancy.

THE MACHINE CONCEPTS SOLUTION

The new coil upender was engineered and built to contain the majority of the machine below the floor. This new pit-style design by Machine Concepts engineers changed the leverage points to relieve stress on the equipment for longevity and made it easier to operate to increase productivity. Previously, the floor-mounted solution required a high torque, high-stress design that put the entire weight of a 40,000-lb coil into the frame of the equipment. Automation also was added.

KEY TECHNOLOGIES

- Coil upender to flip a coil from it side to an upright position.

- Coil car with weigh scales integrated into the machine, which were also calibrated so the measurements could define the weight of the coil to be sold.

- Customized hydraulic power unit to meet Constellium’s unique hydraulic specifications as well as optimized for the performance of the machine.

Transform Your Challenges into Opportunities with a Machine Concepts Solution. Download the full case study below.