Elevating Production with Robotic Routing Cell [Video]

The Customer Challenge

An appliance manufacturer partnered with Machine Concepts to design and build a custom automated cell for a new product and to incorporate into its existing product process. The automated routing cell was designed with low changeover time in mind and less operator intervention. The company could not achieve the desired volumes with manual operation or an existing slower automated operation.

The Machine Concepts Solution

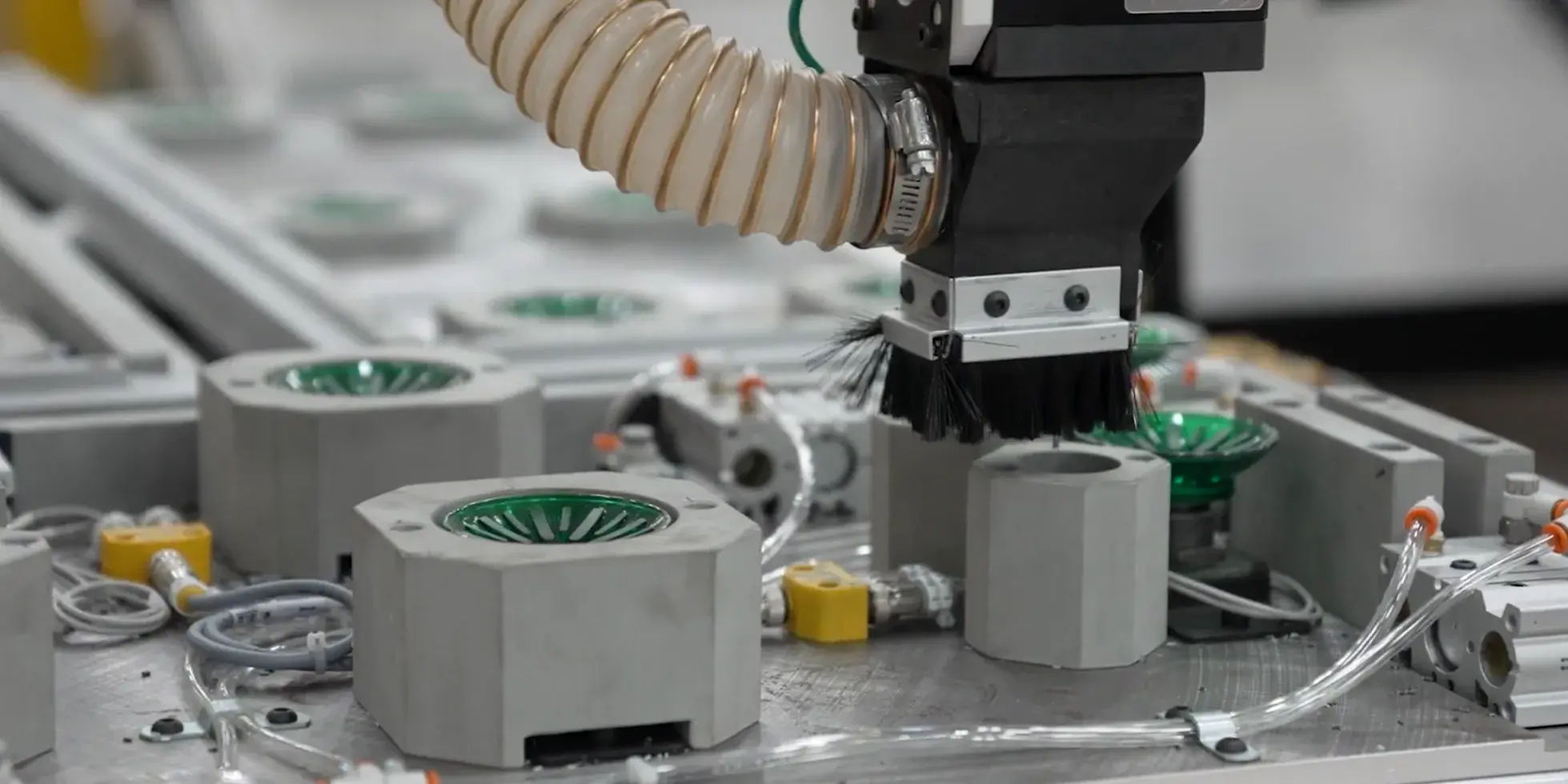

Machine Concepts engineered and manufactured an automated routing cell utilizing three robots with unique end-of-arm tooling and fixtures to drill holes and cut components. The robotic cell can complete one part with 50+ through holes in only 75 seconds. The manual labor needed was reduced significantly to needing human intervention only to load the part into the cell and retrieve it when it exits.

The Process

- First, we started with collaboration. Our team listened to their team to determine what had worked in the past and what could be better.

- We reviewed with them production requirements to develop a plan for cycle time and changeover needs.

- We developed customer drawings to ensure the required tolerances could be maintained.

- We analyzed how much each step of automation would cost for budget requirements and optimal ROI.

- We refined the design until it met efficiency requirements and customer needs.

- We conducted simulation and risk assessments to ensure the validity of the solution.

- Next, we procured and built the machine with prompt updates along the way.

- A full runoff then occurred at our shop with the customer on-site.

- The solution was shipped and installed in the customer facility, and our team trained their team for seamless transition and minimal downtime.

- With operations in place, we provide after-commissioning support as needed.

The Key Technologies

- 3 Fanuc robots

- Custom-designed dual-purpose fixtures

- Vacuum generators and grippers

- Dust collection system

- High-speed motors for routing

- Area scanners, safety interlocks and guarding

- Fully functioning and intuitive HMI and PLC programming

- Fully designed using 3-D software along with simulations to confirm cycle times before building

The Results

- Increased speed and efficiency – 75-second cycle time for complex part

- Increased reliability – robots running 24 hours a day

- Improved accuracy – robots achieve perfect accuracy every time, even with tight tolerances

Machine Concepts Custom Automation Solutions

At Machine Concepts, our specialty is innovative solutions that increase productivity and quality, decrease production costs and improve operator safety. From conceptual design to operational equipment, our team of engineers, skilled machinists and project managers partners with your team to deliver pioneering technologies and machinery that overcome your production challenges. Contact us to talk with one of our engineers today.