Production Time Reduced to Less Than One Minute with Custom, Automated Window Assembly System

THE CUSTOMER CHALLENGE

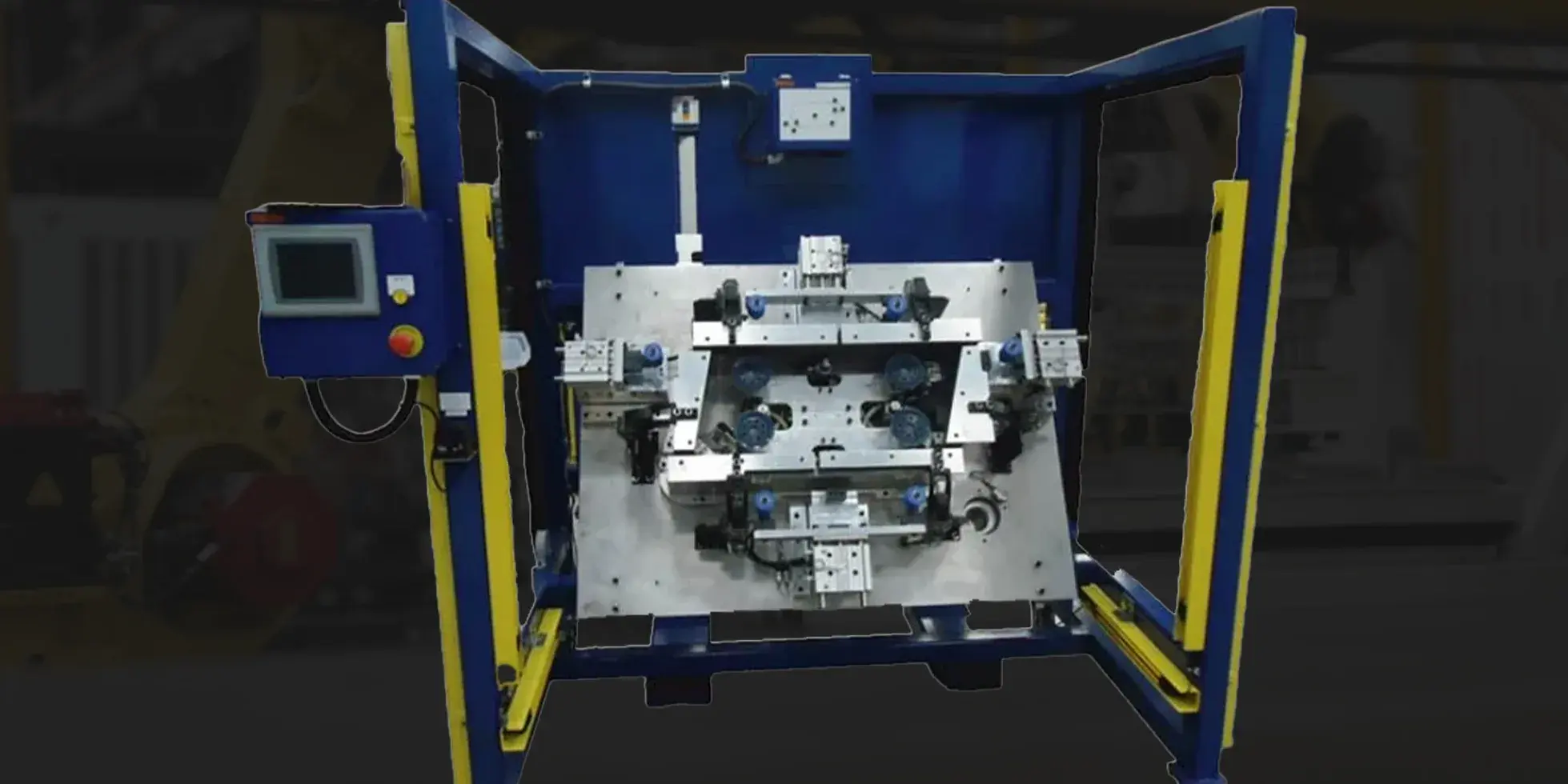

To increase efficiency, an electric automobile manufacturer contracted Machine Concepts to design and build two Automated Automotive Window Assembly Systems to produce install-ready window assemblies for electric automobiles. The push-button operated system attaches weather seal gaskets and installs clips to side and rear window panels.

THE RESULTS

The new “hands-free” automated system reduces the assembly production time to less than one minute.

THE SYSTEM'S KEY TECHNOLOGIES

The heart of the system is a custom designed, shaped, and milled locating fixture. Machine Concepts utilized advanced 3D modeling and 3D machining to manufacture the custom fixtures. This vacuum-assisted fixture automatically centers and holds the glass panes in position during the automated assembly process.

The heart of the system is a custom designed, shaped, and milled locating fixture. Machine Concepts utilized advanced 3D modeling and 3D machining to manufacture the custom fixtures. This vacuum-assisted fixture automatically centers and holds the glass panes in position during the automated assembly process.

To maximize the future value of the equipment, the system has also been designed so that an automated robotic load and unload system can be added.

The production cells utilize Machine Concepts’ custom-designed controls and software loaded onto an Allen-Bradley PLC and HMI. The control system is designed to integrate with the customer’s internal manufacturing network.

For more information, contact Machine Concepts: 419-628-3498 / machineconcepts.com/contact.