Innovative Terminal Equipment for Continuous Lead Casting Line Increases Production

THE CUSTOMER CHALLENGE

A growing manufacturer in the automotive industry was seeking a more efficient, continuous lead casting line to achieve higher productivity in its new manufacturing plant. For the project, the company needed a vendor to supply all the terminal equipment after the rolling mill and, most importantly, to engineer the equipment specifically for processing lead at high temperatures.

The company selected Machine Concepts due to its proven experience and knowledge in custom engineering and building terminal equipment for unique materials such as lead, silver, light gauge steel, aluminum, copper and tin.

THE MACHINE CONCEPTS SOLUTION

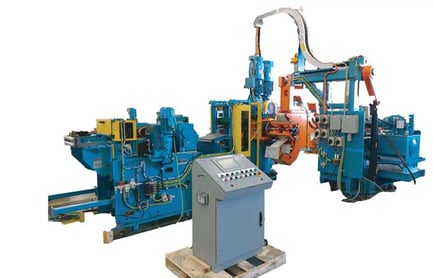

Engineered and built by Machine Concepts, the new terminal equipment for the continuous lead casting line saved floor space, reduced setup time, increased automation and efficiency and boosted production. The equipment was fully integrated with the continuous caster to process the strip directly from the caster to a finished wound coil.

THE KEY TECHNOLOGIES

- Pinch roll

- Side trimmer

- Star chopper

- Full-width abort chopper

- Recoiler

- Coil car

- Belt wrapper

THE RESULTS

Upon exiting the continuous caster, the strip is aligned by a set of entry pinch rolls and side guides. Once aligned, a combination side trimmer/star chopper trims the strip to width. The unique design of the star choppers allows the trim knives and scrap choppers to reside on the same arbors. This efficient design reduces floor space and setup time. The chopped scrap is then removed by a set of conveyors for recycling.

During a coil change sequence, the line automatically goes into abort mode. A custom-designed rotary scrap chopper engages, diverting the strip until the coil change sequence is completed.

To ensure quick coil changes and even winding tension, a highly automated and integrated system consisting of an auto-adjust deflector roll, belt wrapper, turret recoiler and spool detection system are

used. This reduces coil changes to an efficient automated operation.

During coil buildup, the deflector roll adjusts its position relative to the increasing diameter of the coil to ensure consistent even tension on the strip. For quick coil changes, a turret recoiler allows empty coil spools to be pre-staged while the line is in operation. During coil changes, several events are completed simultaneously. The turret recoiler rotates, discharging the processed coil while loading an empty coil spool onto the line. Transform Your Challenges into Opportunities with a Machine Concepts Solution Simultaneously, a spool detection laser system ensures the spool is properly aligned while the belt wrapper engages the strip to begin winding a new coil.

At Machine Concepts, we design and build

a wide range of turnkey coil processing

equipment. With extensive experience in

both mill and service center applications,

we can engineer innovative solutions for the most demanding requirements.

For more information, contact Machine Concepts: 419-628-3498 / machineconcepts.com/contact.