Dead Flat & Spot On: New 84” Wide Tension Leveler Increases Production & Efficiency

THE CUSTOMER CHALLENGE

THE CUSTOMER CHALLENGE

As part of a recent expansion project, JW Aluminum in Goose Creek, South Carolina, was in need of a new wide tension leveler to process wider coils that were now produced by its new melters, caster and mill. JW Aluminum turned to Machine Concepts.

THE SOLUTION

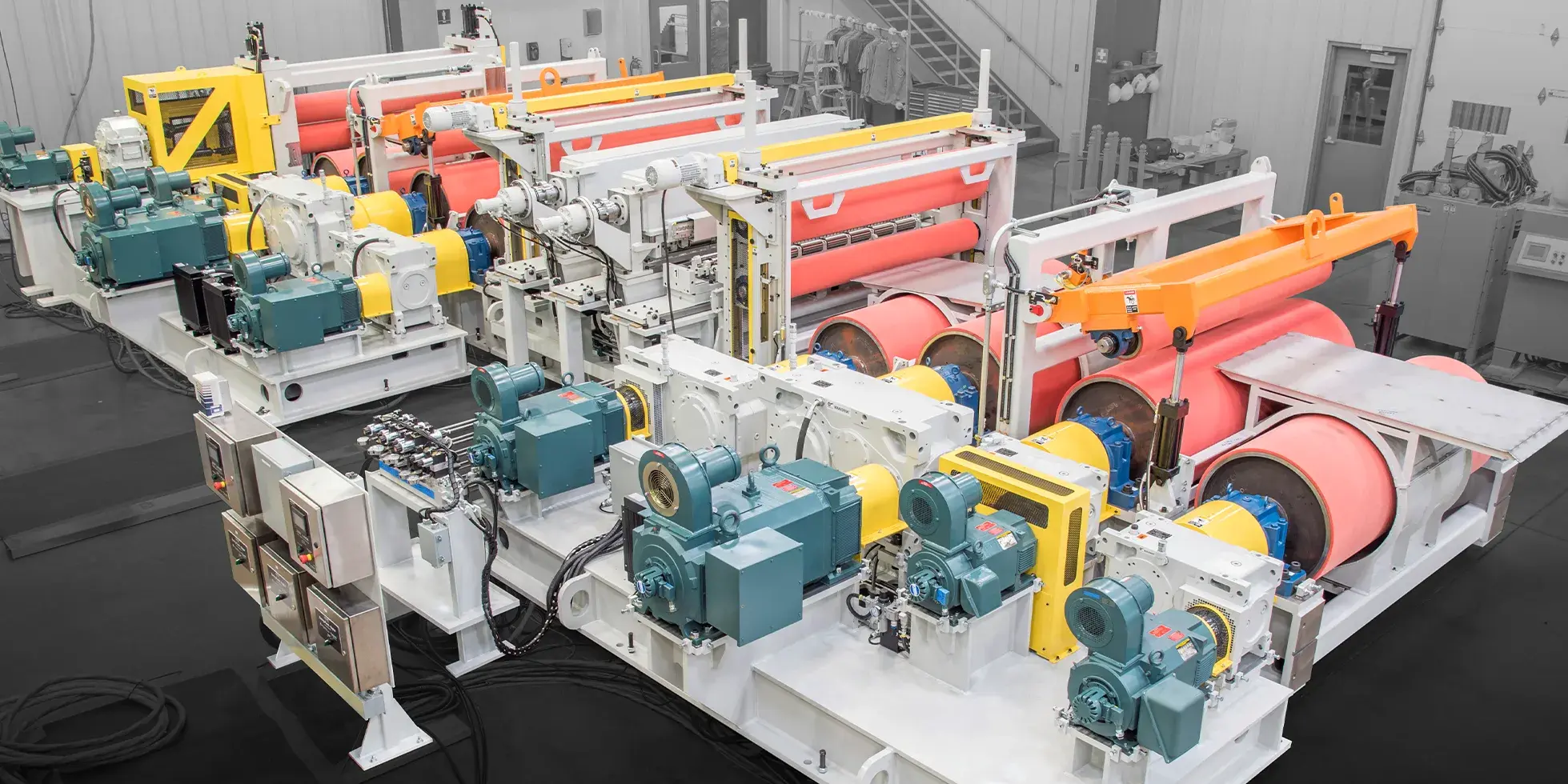

Machine Concepts engineered and built one of the industry’s widest tension levelers at an impressive 84 inches (7 feet) wide with serious leveling capabilities to support JW Aluminum in its expansion and increased production capabilities.

THE LEVELER’S KEY TECHNOLOGIES

The highly automated, push-button operating system designed and built by Machine Concepts is comprised of:

- The leveler system is a 6-high configuration comprising a set of entry and exit bridle roll stands with a series of work rolls placed between them.

- For the highest efficiency, the tension leveler incorporates an advanced, custom-designed control system that is push-button and automated. This allows the tension leveler to automatically set the amount of tension required based on the material specifications and the amount of elongation required.

- The system incorporates a continuous material lubrication system that adjusts the amount of lubricant applied based on speed and material.

- The leveling system incorporates an entry deflector roll used to ensure proper entry work roll wrap angle.

- An exit anti-cross bow roll is used on the exit side to properly control and remove unwanted cross bow induced into the strip.

The cell also features areas for tool storage, allowing for quick changes to the robot end-of-arm tooling and part locating fixtures

THE RESULTS

- The system has a thickness range capacity of 0.015” to 0.080” with a maximum yield strength of 37,000 psi.

- The elongation capacity range is from 0.5% to as much as 2% depending on material thickness.

- The high-speed system can process aluminum coils at speeds of up to 1,000 feet per minute.

- The system has the capacity to produce stress free material as flat as (0) I units. This is dead flat.

SUSTAINABILITY

To lower cost, address energy consumption and provide a green solution, the entry bridle roll motors incorporate two capabilities:

- The motors provide the back tension needed for tension leveling.

- The motors incorporate “regenerative drive” capabilities, meaning they have the ability to generate electricity that is then used to supplement the energy required for the exit bridle drive motors. This greatly reduces the energy costs to operate the system.

For fast and seamless maintenance, both bridle roll stands incorporate a unique split pillow block design allowing easy removal of any bridle roll. If damaged or worn, any bridle roll can be removed, ground and replaced without affecting the system.

Furthermore, the upper and lower work rolls are incorporated into roll modules for quick inspection and cleaning. The lower work roll modules exit the line via a powered hydraulic cylinder system, while the upper work roll modules rotate 180 degrees from their working position to easily expose the work rolls.

For more information, contact Machine Concepts: 419-628-3498 / machineconcepts.com/contact.