Precision Roller Leveler with Patented Technology Increases Quality, Productivity & Efficiency

THE CUSTOMER CHALLENGE

Pacesetter, a leading provider of galvanized, prepaint, cold-rolled, aluminized and stainless steel, was in need of an advanced precision roller leveler that provided versatility and increased production numbers at its NSPS facility in Houston, Texas. Having already had a successful partnership with Machine Concepts on a precision roller leveler, the Pacesetter team again turned to the engineers at Machine Concepts for a custom solution.

THE SOLUTION

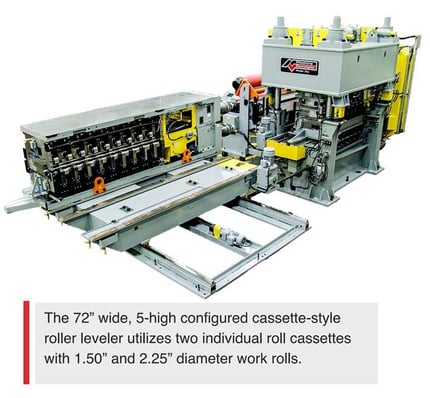

As an industry-leading designer and builder of roller levelers and coil processing equipment, Machine Concepts engineered and installed for Pacesetter a G3DC Cassette Style Precision Roller Leveler with patented AutoSync™ Drive and patented Roll Cleaning System.

THE RESULTS

The G3DC Cassette Style Precision Roller Leveler with patented technologies processes a wider thickness range of 0.015” to 0.140” for cold rolled, hot rolled, hot rolled P&O, galvanized, prepaint and stainless steel.

The G3DC Cassette Style Precision Roller Leveler with patented technologies processes a wider thickness range of 0.015” to 0.140” for cold rolled, hot rolled, hot rolled P&O, galvanized, prepaint and stainless steel.

Depending on the application, the ultra-fast driven leveler can reach production speeds as high as 400 fpm.

For the highest possible efficiency, the leveler utilizes a push-button operated system for cassette exchanges. This system consists of a series of pneumatic clamps located on the leveler frame and a powered cassette transport system with an offline holding table. With the push of a button, the leveler closes and the pneumatic clamps release, allowing the work roll cassette to be removed. The transport system removes the roll cassette from the leveler and onto a cassette holding table located next to the leveler. Once placed on the table, the table shifts over, aligning the second roll cassette with the leveler frame. The second roll cassette is then loaded into the leveler frame. The pneumatic clamps re-engage and lock the cassette into place.

This system eliminates manually bolting and unbolting the roll cassettes. With a simple push of a button, cassette exchanges are initiated, saving time and increasing overall production.

THE LEVELER’S KEY TECHNOLOGIES

To address higher quality standards, the cassette leveler utilizes Machine Concepts’ exclusive pivot-style roll bending system. This system allows for customized and location-specific roll bending to produce a more stable, flatter product.

When an adjustment is made to bend the work rolls for leveling, the adjustment is not constant throughout the entire length of the machine as it is with other designs. Instead, the adjustment is focused on the entry side of the leveler. The pivot mount system reduces the amount of adjustment over the length of the leveler by feathering out the penetration from entry to exit, thereby allowing the exit work roll geometry to stay consistent and flat. This method eliminates the need to adjust the crown of the leveler to compensate for roll bending and produces a flatter and more stable product.

The leveler also features Machine Concepts’ patented Roll Cleaning System. When processing surface-critical materials, keeping the work rolls clean is paramount to producing a high-quality product. The leveler has the ability to open a full 6 inches, allowing easy access to the work rolls. A cleaning pad is placed in the leveler. The automatic cleaning system will close the leveler and run the top and bottom work rolls in opposite directions, reversing rotation multiple times to clean the work rolls. This reduces cleaning to a push-button operation.

The cassette leveler features Machine Concepts’ patented AutoSync™ Drive. This drive system separates the entry and exit work rolls into clusters to allow for different rotation speeds for more efficient use of energy, thereby reducing operating costs. Energy consumption can be reduced by as much as 20% depending on the application when compared to a standard roller leveler. Additionally, allowing for different rotation speeds reduces the torque differential within the drive train, thereby extending the life of the drive components. It also produces a flatter and more stable product.

For more information, contact Machine Concepts: 419-628-3498 / machineconcepts.com/contact.